Large, thin tiles have become great trend in the ceramic industry and lately the market has responded with higher demands for those sizes. However, manufacturing these big slabs involves some big challenges. The difficulties tile makers face when producing these sizes are related to the mechanics of the tile, the manufacturing methods and the raw materials. One of the greatest challenges has been the conflicts in Ukraine, where most of the clay to manufacture these types of tiles comes from. This has affected significantly the market pricing.

Replace Ukrainian clay and maintain quality in your tile production

By Yaiza Paños 29-Jan-2020 15:37:21

Temaer: Decorative, large tiles, Clay additives, optimization, cost reduction

Importance of technical support in the use of structural clay additives

By Jonathan Savage 10-Jan-2020 13:04:33

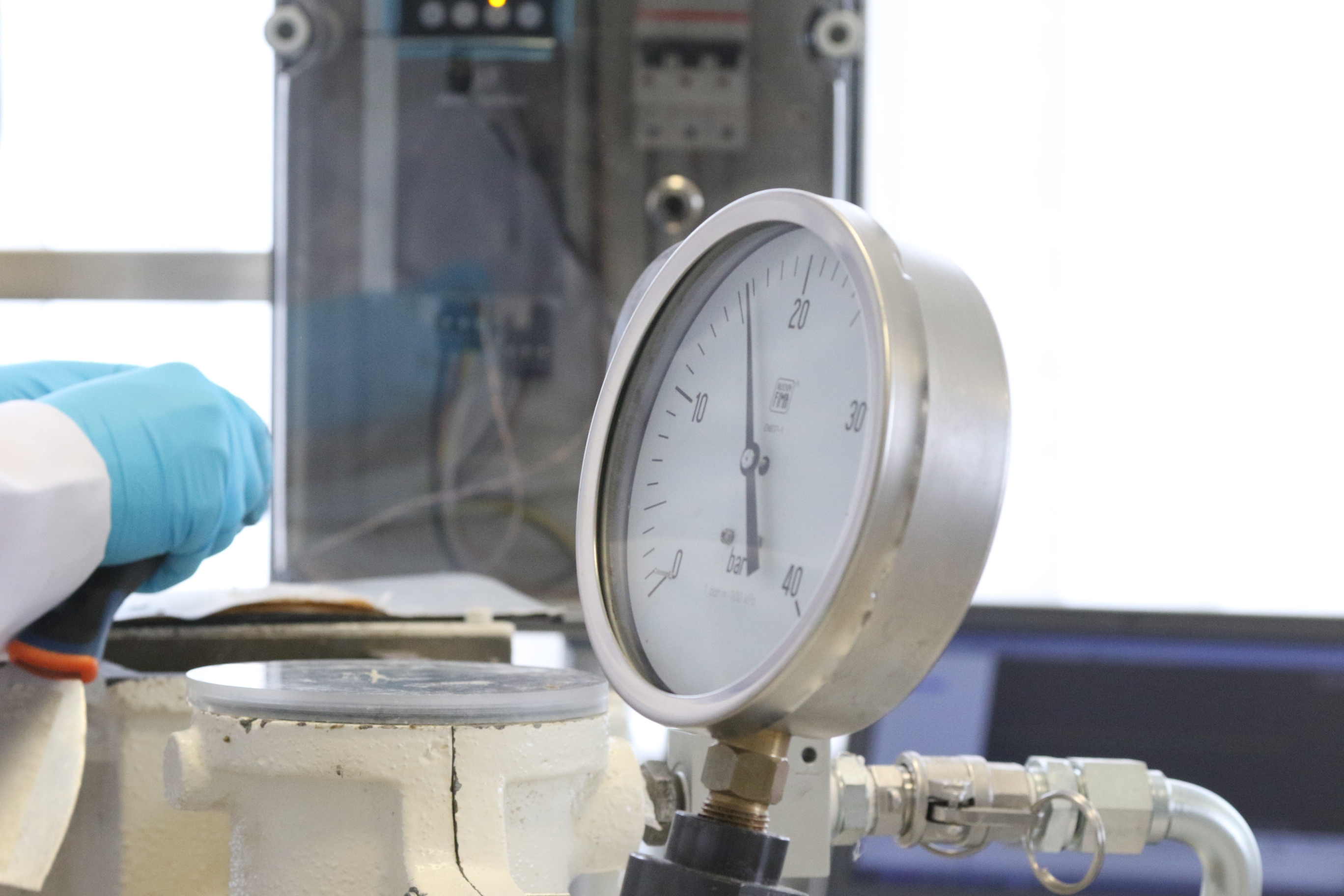

Technical support is key to ensure that you are using the right clay additive at the correct addition rate. We should always count on a technical specialist, in order to achieve the maximum efficiency of your process and depending on what you are using our additives for, we should take different actions and carry out specialized tests.

Temaer: Structural, Clay additives, optimization, bricks, technical support

Raw materials are the most crucial part of making quality bricks. Consistent, high quality raw materials combined with sound processes normally result in good quality fired ware. Unfortunately, in the real world, raw materials vary in quality and consistency. Variations in raw materials such as particle size, fired color, carbon content, and shrinkage are routinely measured during exploration, mining, stockpiling, and production. Another characteristic of raw materials that is critical and should be measured and monitored is the level of soluble sulfates present in the raw materials used to make brick.

Temaer: Structural, Ceramics, Green Strength, optimization, Tools

This month we will focus on the importance of testing and measuring results to optimize production. Both on small and large scale, measuring and analyzing results will definitely help you increase your production efficiency.

Temaer: Question of the month, optimization

Ceramic tiles may present some issues during their manufacturing process. Most of them do not have an origin in the process itself, but in the raw materials used in the production line. A proper control in the raw materials and in the process will minimize the potential risks of producing second class materials.

Temaer: Decorative, optimization, Tools

In today’s economic climate and with manufacturers desire to ensure strong sales whilst optimizing profits what options are open to help reduce costs in production?

One could probably summarize that the “easiest” options available to reduce costs could be raw materials, production, drying and firing and reducing losses - in fact it could be argued that all of these options go hand in hand.

Temaer: Structural, Clay additives, optimization, bricks, cost reduction

In a competitive market like we have in ceramics in the last years, globalized, with common solutions to the standard production issues, differentiation in costs is the only way to remain competitive. So, how much could we save?

Temaer: Decorative, case study, optimization, cost reduction

Decorative ceramics are characterized by fast firing cycles with values below 30 minutes in some countries. Of course this is not the standard value, but it gives an idea of how well adapted these kilns are to fast firing. At the same time, being one of the main polluting points in decorative ceramics manufacturing process, lots of efforts have been dedicated in order to reduce CO2 emissions, as well as some other highly pollutants (NOx, HCl, HF, heavy metals, Sox, VOCs, among others).

The next challenge in the horizon will be automation, though a lot of improvements have been done in order to bring self-regulation and high optimization of the full firing process.

Temaer: Decorative, optimization, kilns

Kiln firings: History, development and types of Structural kilns

By Jonathan Savage 14-Mar-2019 13:17:57

Throughout the centuries of brick and tile making the manufacturing, drying and the firing of the products has continued to evolve to ensure demand, styles and supply are met. However although manufacturing and drying are based on a small number of routes which continue to evolve the firing process has probably seen the most changes over this time frame.

Temaer: Structural, Clay additives, optimization, bricks, kilns

Clay bricks have featured as a construction product for thousands of years with evidence of their use dating as far back as the time of the Roman Empire. It is a material prevalent across the UK's built environment today and continues to be a fundamental ingredient in modern architecture.

Temaer: Structural, Clay additives, optimization, bricks